Precision and Power: Exploring the Advancements in Robotic Welding Machines

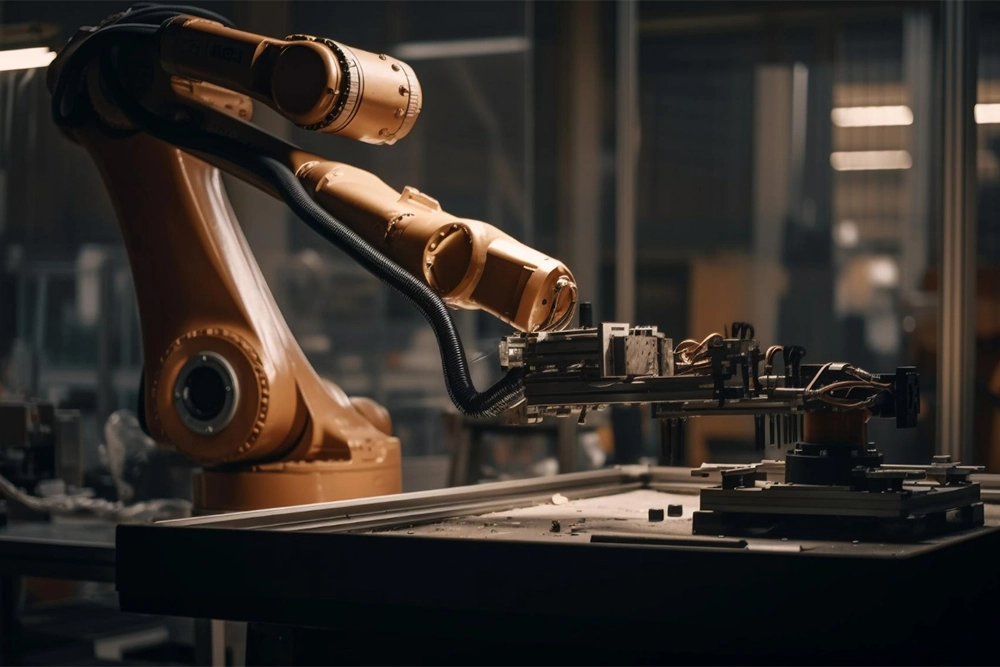

Imagine a world where every weld is flawless, every joint perfectly aligned, and every project completed with unprecedented speed and precision. This is the promise of robotic welding, a technology that has transformed the landscape of manufacturing and construction.

The Evolution of Robotic Welding

The journey of robotic welding began with the need for consistent and high-quality welds in industrial settings. Traditional manual welding, while effective, often led to inconsistencies due to human error and fatigue. The introduction of robotic welding machines marked a significant leap forward, offering unmatched accuracy and repeatability.

Key Advancements in Robotic Welding Machines

1. Precision and Accuracy: Modern robotic welding machines are equipped with advanced sensors and control systems that ensure each weld is performed with pinpoint accuracy. This precision reduces the risk of defects and enhances the overall quality of the finished product.

2. Increased Speed and Efficiency: Automation in welding processes has dramatically increased production speeds. Robots can operate continuously without breaks, leading to higher throughput and faster project completion times. This efficiency is particularly crucial in industries where meeting tight deadlines is essential.

3. Versatility and Flexibility: Robotic welding systems are highly adaptable, capable of handling a wide range of welding techniques and materials. From MIG and TIG welding to spot welding, these machines can be programmed to meet specific requirements, making them ideal for diverse applications.

4. Enhanced Safety and Reduced Labor Costs: By taking over hazardous welding tasks, robotic systems significantly improve workplace safety. They reduce the risk of exposure to harmful fumes and extreme heat, protecting workers from potential injuries. Additionally, the use of robotic welding can lead to cost savings by minimizing the need for skilled labor.

The Future of Robotic Welding

As technology continues to evolve, the future of robotic welding looks promising. Advances in artificial intelligence and machine learning are expected to further enhance the capabilities of these machines. Predictive maintenance, real-time monitoring, and adaptive control systems will enable even greater precision and efficiency in welding processes.

Embracing the Future with Robotic Welding

The integration of robotic welding machines in industrial processes has revolutionized the way we approach manufacturing and construction. With their unmatched precision, speed, and versatility, these machines are paving the way for a future where welding is more efficient, safe, and reliable than ever before. As we continue to push the boundaries of technology, the potential for robotic welding is limitless, promising a new era of innovation and excellence in the industry.