Unleashing Precision: The Advantages of Tooling and Die Design

Imagine a world where every product you use is flawlessly crafted, with each part fitting perfectly. This is the promise of advanced tooling and die design—an often overlooked yet crucial aspect of modern manufacturing.

Introduction

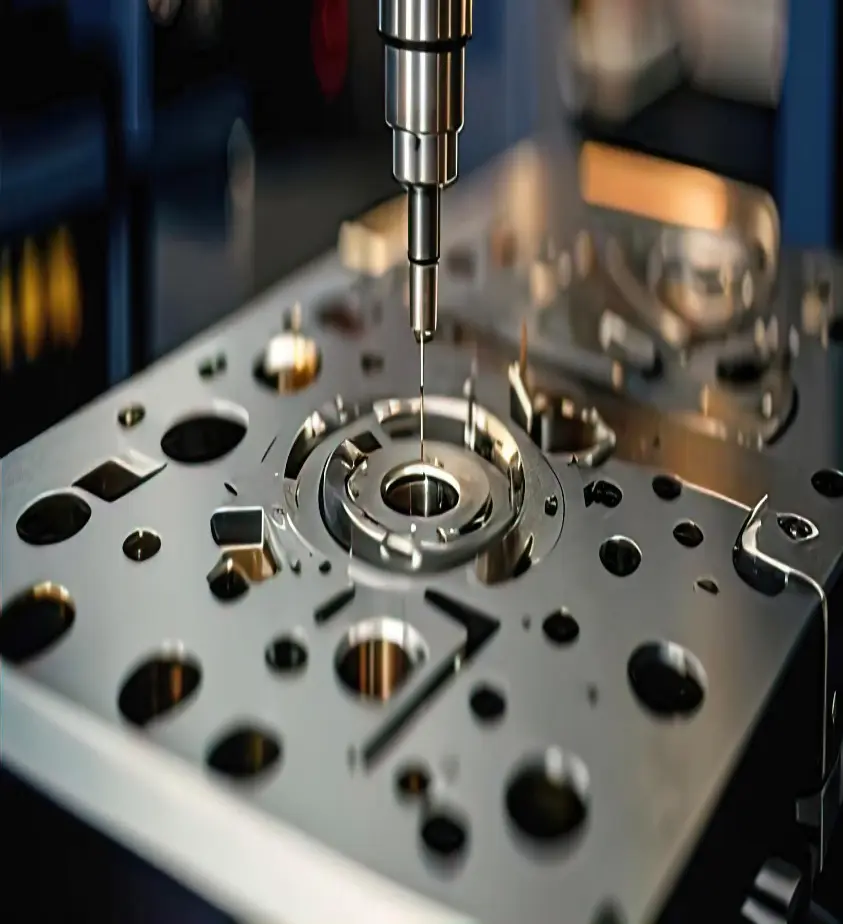

In the manufacturing world, tooling and die design plays a pivotal role in ensuring the production of high-quality components. This process involves creating specialized tools and dies, which are essential for shaping and forming materials into precise, complex shapes. Let's delve into the numerous advantages that make tooling and die design an indispensable part of the production industry.

Key Advantages of Tooling and Die Design

1. Enhanced Precision and Accuracy

One of the foremost benefits of tooling and die design is the unparalleled precision it offers. Custom-designed tools and dies allow manufacturers to produce parts with exact specifications, ensuring a high level of accuracy. This precision is critical in industries like automotive and aerospace, where even the smallest deviation can have significant consequences.

2. Increased Efficiency and Productivity

Tooling and die design streamline the manufacturing process by reducing the need for manual adjustments and interventions. Once a die is created, it can be used repeatedly, producing identical components with minimal variation. This consistency not only speeds up production but also reduces material waste, making the process more efficient and cost-effective.

3. Cost Savings

While the initial investment in tooling and die design can be significant, the long-term savings are substantial. The durability and repeatability of well-designed dies reduce the cost per unit over time. Moreover, the ability to produce parts in large quantities without compromising quality results in economies of scale, further lowering production costs.

4. Improved Product Quality

The use of precise tools and dies ensures that each product meets stringent quality standards. This consistency in quality enhances the reputation of manufacturers and builds trust with consumers. Additionally, the ability to create complex shapes with minimal defects results in superior products that perform better and last longer.

5. Customization and Flexibility

Tooling and die design offer the flexibility to create customized solutions tailored to specific manufacturing needs. Whether it's a unique part design or a special material requirement, custom dies can accommodate a wide range of specifications. This adaptability is invaluable in industries where innovation and differentiation are key to staying competitive.

In conclusion, tooling and die design is a cornerstone of modern manufacturing, offering unparalleled benefits in terms of precision, efficiency, cost savings, and product quality. As industries continue to evolve, the role of advanced tooling and die design will only become more crucial in meeting the demands of high-quality, efficient production. By investing in top-notch tooling and die design, manufacturers can ensure their products not only meet but exceed the expectations of their customers, paving the way for success in an increasingly competitive market.