Revolutionizing Manufacturing: The Latest in Plastic Injection Molding Parts

The world of manufacturing is constantly evolving, and at the forefront of this transformation is plastic injection molding technology. Recent advancements have significantly enhanced the efficiency, sustainability, and versatility of this pivotal process. This blog delves into the latest updates in plastic injection molding parts, offering insights into how these innovations are reshaping industries.

Enhanced Material Efficiency

The latest strides in material science have led to the development of more efficient and sustainable plastics. These materials not only reduce waste but also extend the life cycle of injection-molded parts, making them a more eco-friendly option for manufacturers.

Innovations in biopolymers and recycled plastics are paving the way for a greener future in plastic injection molding. These materials offer comparable strength and flexibility to traditional plastics while significantly reducing the carbon footprint of production processes.

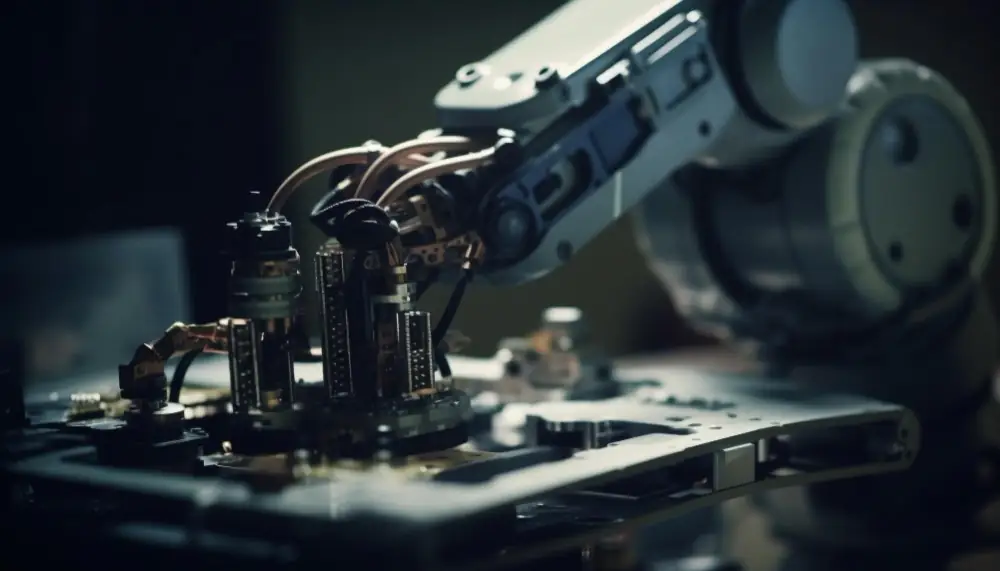

Advanced Molding Technologies

Recent advancements in molding technologies have introduced precision and speed to the production line, allowing for more complex part designs and faster turnaround times.

3D printing and AI-driven predictive modeling have revolutionized the design and prototyping phases of injection molding. These technologies enable manufacturers to identify and rectify potential issues before they arise, ensuring a smoother production process and higher quality parts.

Sustainable Practices

The injection molding industry is increasingly adopting sustainable practices, from energy-efficient machinery to waste reduction techniques. By integrating smart technologies and renewable energy sources, manufacturers are not only minimizing environmental impact but also reducing operational costs. These practices underscore the industry's commitment to sustainability without compromising on quality or efficiency.