The Future of Manufacturing: Innovations in Progressive Die Stamping

Progressive die stamping stands as a beacon of innovation in the manufacturing sector, revolutionizing how components are mass-produced with precision, speed, and cost-efficiency. This process, which involves the transformation of a metal strip into a complete product through a series of stamping stations, has seen significant advancements in recent years. This blog delves into the latest innovations and their implications for the future of manufacturing, exploring how these advancements enhance productivity, reduce waste, and cater to the increasingly complex demands of various industries.

Introduction to Progressive Die Stamping

Explore the basics of progressive die stamping, its key components, and how it differs from other stamping processes. This section sets the stage for understanding the significance of recent innovations in the field.

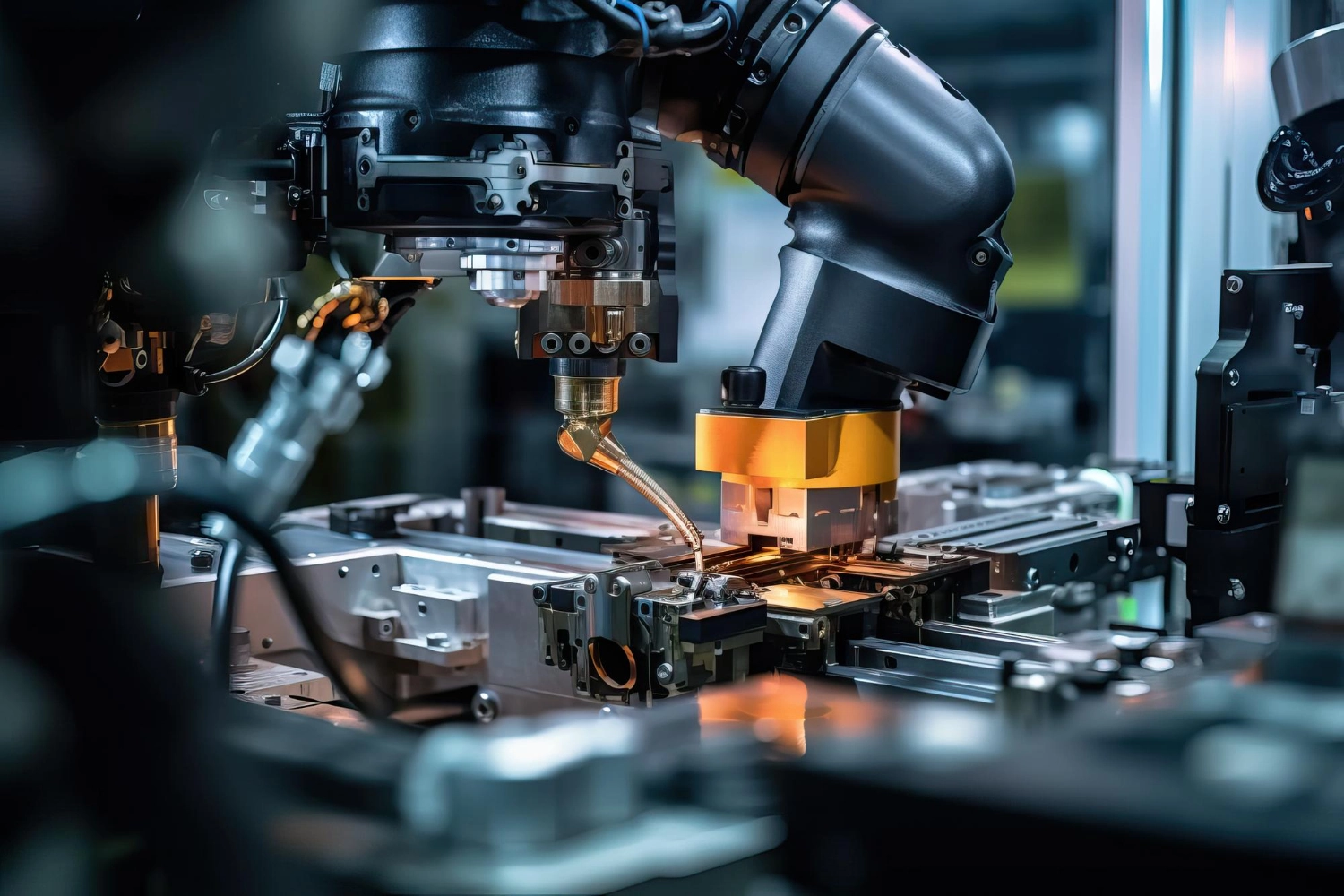

Technological Advancements in Progressive Die Stamping

Discuss the cutting-edge technologies being integrated into progressive die stamping, such as automation, high-speed cameras for real-time inspection, and software for predictive maintenance and design optimization. This part highlights how these technologies are making the process faster, more reliable, and less costly.

Material Innovations

Examine the development of new materials and coatings that are expanding the capabilities of progressive die stamping, including high-strength alloys and sustainable, eco-friendly materials. This section explains how these materials are enabling the production of more durable and complex components.

Impact on Industries

Detail the effects of progressive die stamping innovations on various sectors, including automotive, aerospace, and electronics, emphasizing how these advancements support the creation of lighter, more efficient, and higher-quality products.

The Future of Progressive Die Stamping

Speculate on future trends in the industry, such as the integration of artificial intelligence and the potential for further automation. This final part considers how ongoing innovation will continue to shape the landscape of manufacturing.