Revolutionizing Manufacturing: The Future of Progressive Die Stamping

In the rapidly evolving world of manufacturing, progressive die stamping stands out as a cornerstone for efficiency and innovation. This blog post delves into the latest advancements and trends shaping the future of progressive die stamping, a process known for its precision and cost-effectiveness in producing high-volume metal parts. From technological breakthroughs to sustainability efforts, we explore how this field is adapting to meet the demands of modern manufacturing.

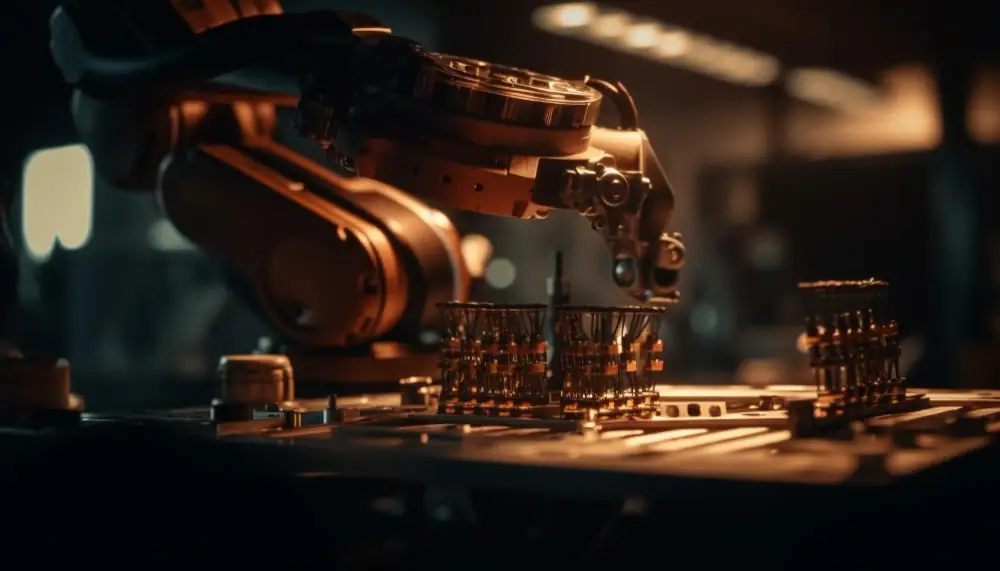

1. Technological Advancements in Progressive Die Stamping

- This section highlights the cutting-edge technologies being integrated into progressive die stamping, such as automation, AI-driven quality control, and advanced materials. We discuss how these innovations enhance precision, speed, and flexibility in production lines, pushing the boundaries of what's possible in metal fabrication.

2. Sustainability and Efficiency Gains

- Focusing on the environmental aspects, this part examines how the industry is making strides towards sustainability. It covers the use of recyclable materials, energy-efficient processes, and waste reduction techniques that are not only eco-friendly but also cost-effective, ensuring a greener future for manufacturing.

3. The Impact of Digital Transformation

- Here, we explore the role of digital transformation in progressive die stamping, from digital twins and predictive maintenance to cloud computing and the Internet of Things (IoT). These digital tools offer unprecedented opportunities for optimizing production processes, enhancing customization, and reducing downtimes.

4. Challenges and Opportunities Ahead

- This concluding section discusses the challenges facing the progressive die stamping industry, such as the skilled labor shortage and global supply chain issues. It also looks at the opportunities these challenges present for innovation and growth, setting the stage for the next era of manufacturing excellence.