Understanding the Basics of Progressive Die Stamping

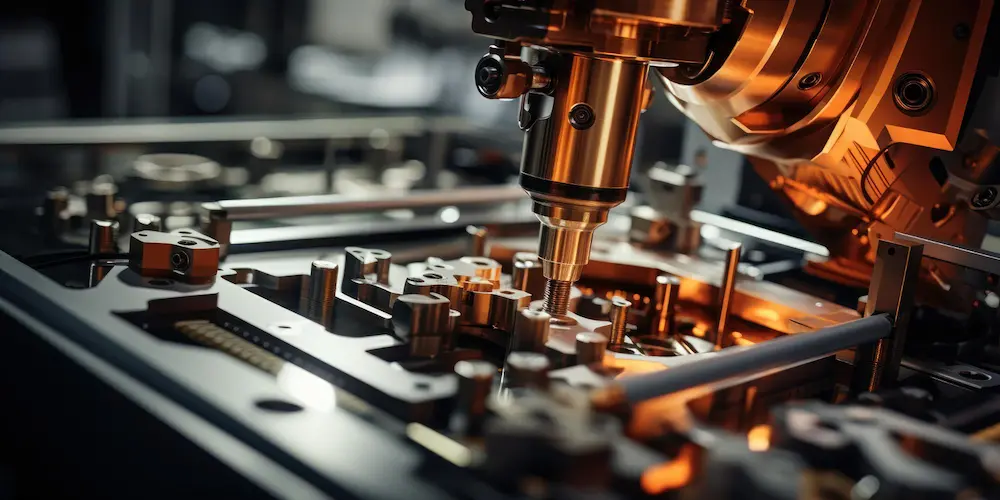

Ever wondered how complex metal parts are made with such precision and efficiency? The secret lies in the technology of progressive stamping die!

Introduction

Progressive die stamping is a crucial technology in the manufacturing industry, enabling the production of complex metal parts with high precision and efficiency. This blog will delve into the fundamentals of progressive die stamping, its applications, and the benefits it offers.

What is Progressive Stamping Die?

Progressive stamping die is a metalworking process that uses a series of stamping stations. Each station performs a specific operation on the metal strip as it passes through the die, ultimately creating a finished part. This process is highly efficient and ideal for producing large quantities of parts with consistent quality.

Key Components of Progressive Stamping Die

1. Die Block

The die block is the foundation of the stamping die, housing all the essential components. It ensures stability and precision during the stamping process.

2. Punch

The punch is responsible for cutting and shaping the metal strip. It works in conjunction with the die block to create the desired shape and features of the part.

3. Stripper Plate

The stripper plate holds the metal strip in place, ensuring it stays aligned during the stamping process. This prevents any misalignment that could lead to defects.

4. Pilot Pins

Pilot pins guide the metal strip through each station, ensuring it moves smoothly and accurately from one operation to the next.

Applications of Progressive Stamping Die

1. Automotive Industry

Progressive die stamping is widely used in the automotive industry to produce parts like brackets, connectors, and clips. The high precision and efficiency of this process make it ideal for mass production.

2. Electronics Industry

In the electronics industry, progressive die stamping is used to manufacture connectors, terminals, and other small components. The process ensures consistent quality, which is crucial for electronic devices.

3. Aerospace Industry

The aerospace industry relies on progressive stamping die for producing lightweight and high-strength components. The precision of this process is vital for maintaining the safety and reliability of aerospace parts.

Benefits of Progressive Stamping Die

1. High Efficiency

Progressive stamping die allows for the production of multiple parts in a single operation, significantly reducing manufacturing time and costs.

2. Consistency and Precision

The process ensures that each part produced is of consistent quality and precise dimensions, which is essential for industries requiring high reliability.

3. Cost-Effective

By reducing the need for multiple tools and setups, progressive stamping die minimizes production costs, making it a cost-effective solution for large-scale manufacturing. Understanding the basics of progressive stamping die is essential for appreciating its impact on modern manufacturing. This technology not only enhances production efficiency but also ensures high-quality output, making it indispensable in various industries. As manufacturing continues to evolve, the importance of progressive stamping die will only grow, driving innovation and excellence in the production of complex metal parts.