Revolutionizing Production Lines: Latest Trends in Automated Assembly Systems

In the dynamic landscape of manufacturing, efficiency is key. As industries evolve, so do the methods of production. Automated assembly systems have emerged as a game-changer, revolutionizing traditional manufacturing processes. Let's delve into the latest trends shaping the automated assembly systems industry.

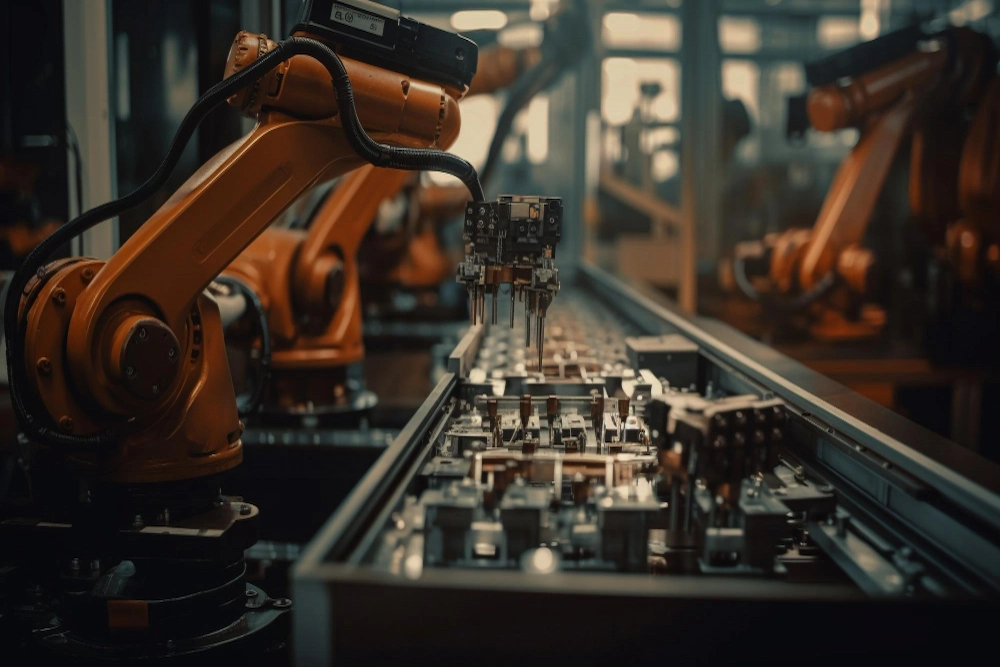

Robotics Integration:

Robots are no longer confined to sci-fi fantasies; they're integral to modern production lines. With advancements in AI and machine learning, robots are becoming more adaptive and versatile. From precision handling to complex assembly tasks, robotics integration streamlines operations, reducing cycle times and enhancing accuracy.

IoT and Connectivity:

The Internet of Things (IoT) has transformed the way machines communicate. In automated assembly systems, IoT enables seamless connectivity between devices, facilitating real-time monitoring and data analysis. Predictive maintenance, remote diagnostics, and optimized workflows are just a few benefits of IoT integration.

AI-driven Optimization:

Artificial Intelligence (AI) algorithms are optimizing assembly processes like never before. Machine learning algorithms analyze vast datasets to identify patterns and anomalies, optimizing production schedules and resource allocation. AI-driven predictive analytics minimize downtime and maximize throughput, ensuring peak efficiency.

Collaborative Robotics (Cobots):

Collaborative robots, or cobots, are revolutionizing human-robot interaction on the assembly line. Unlike traditional industrial robots, cobots can work alongside human operators safely. With built-in sensors and adaptive control systems, cobots enhance flexibility and agility, enabling efficient human-robot collaboration.

Additive Manufacturing Integration:

Additive manufacturing, commonly known as 3D printing, is increasingly integrated into automated assembly systems. 3D printing enables rapid prototyping and customized part production, reducing lead times and material waste. By incorporating additive manufacturing into assembly processes, manufacturers achieve unparalleled design freedom and cost savings.

The evolution of automated assembly systems is relentless, driven by technological innovation and market demands. Embracing these latest trends empowers manufacturers to stay competitive in a rapidly evolving landscape. From robotics integration to AI-driven optimization, the future of manufacturing is automated and efficient.

In conclusion, the future of manufacturing is here, and automated assembly systems are leading the way. Are you ready to embrace the revolution?